Is Higher Compressive Strength Always Better?

With a lot of construction projects it is thought that the stronger the building elements, the stronger the project. Each material should be the strongest it can be to withstand the pressures and the weight of the rest of the build, But are there other factors that should be considered? Could there be scenarios where the strength is overcompensated, at the detriment of other important standards. The team at Armatherm has experienced these questions numerous times, with customers looking for the highest possible compressive strength no matter what the project or application is.

Why Selecting the Right Thermal Break Strength Matters

We appreciate the importance of safety factors when engineering buildings, but there is a point at which more is not necessarily better. Because inserting thermal breaks into structural connections is becoming standard practice, choosing the right strength and density of thermal breaks is important to achieve design goals. Armatherm has several thermal break materials to choose from to help with this.

What Happens When You Over-Specify Strength

Typically, any thermal break material with lower compressive strength capacity tends not to absorb water and has very limited creep under load. Because of this, energy lost via thermal bridges can be massively reduced. The lower the compressive strength of a material the higher the R value, and so finding the best balance between insulation and strength is key. The compressive strength must be sufficient enough to withstand the loads of the connections, but not so overcompensated as to be detrimental to the R value which is needed to improve efficiency and meet strict regulations.

Another factor that suffers when opting to overcompensate with compressive strength, is the project budget. The thermal break materials with higher compressive strength are typically more expensive, so when these materials are utilized for a project which doesn’t require them, budget can be wasted. The team at Armatherm is dedicated to ensuring the correct materials are selected from the diverse range we provide. We are the only thermal bridging solutions manufacturer globally to offer such a variety of products on the market.

Why Thermal Breaks Are Essential for Net-Zero Design

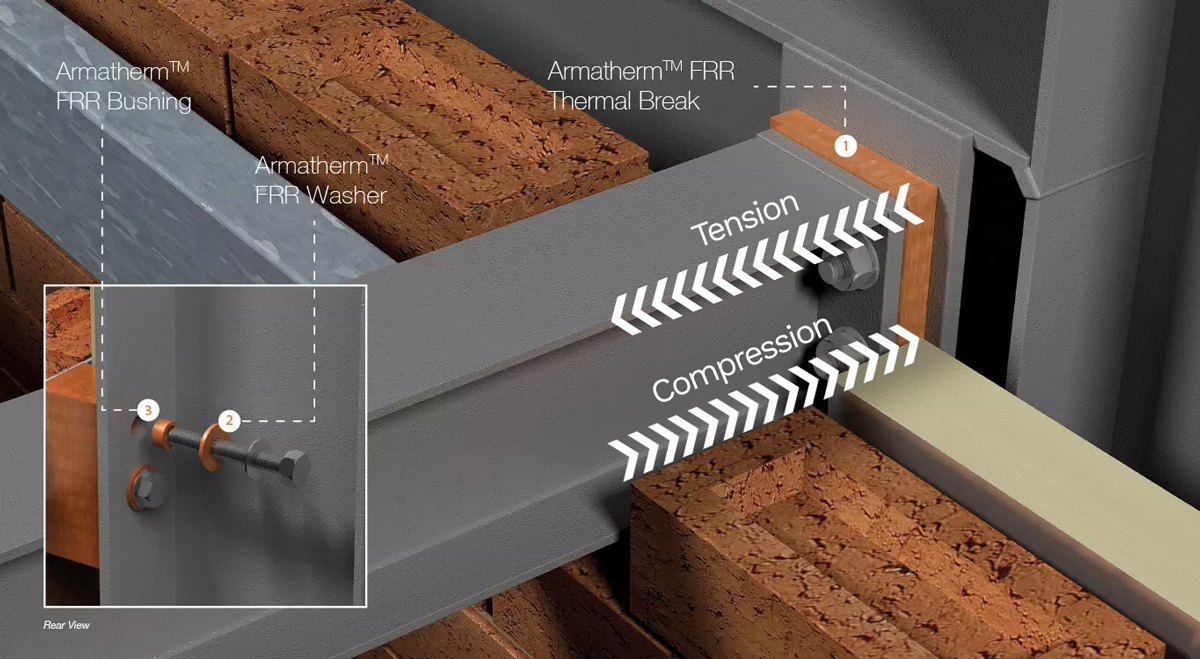

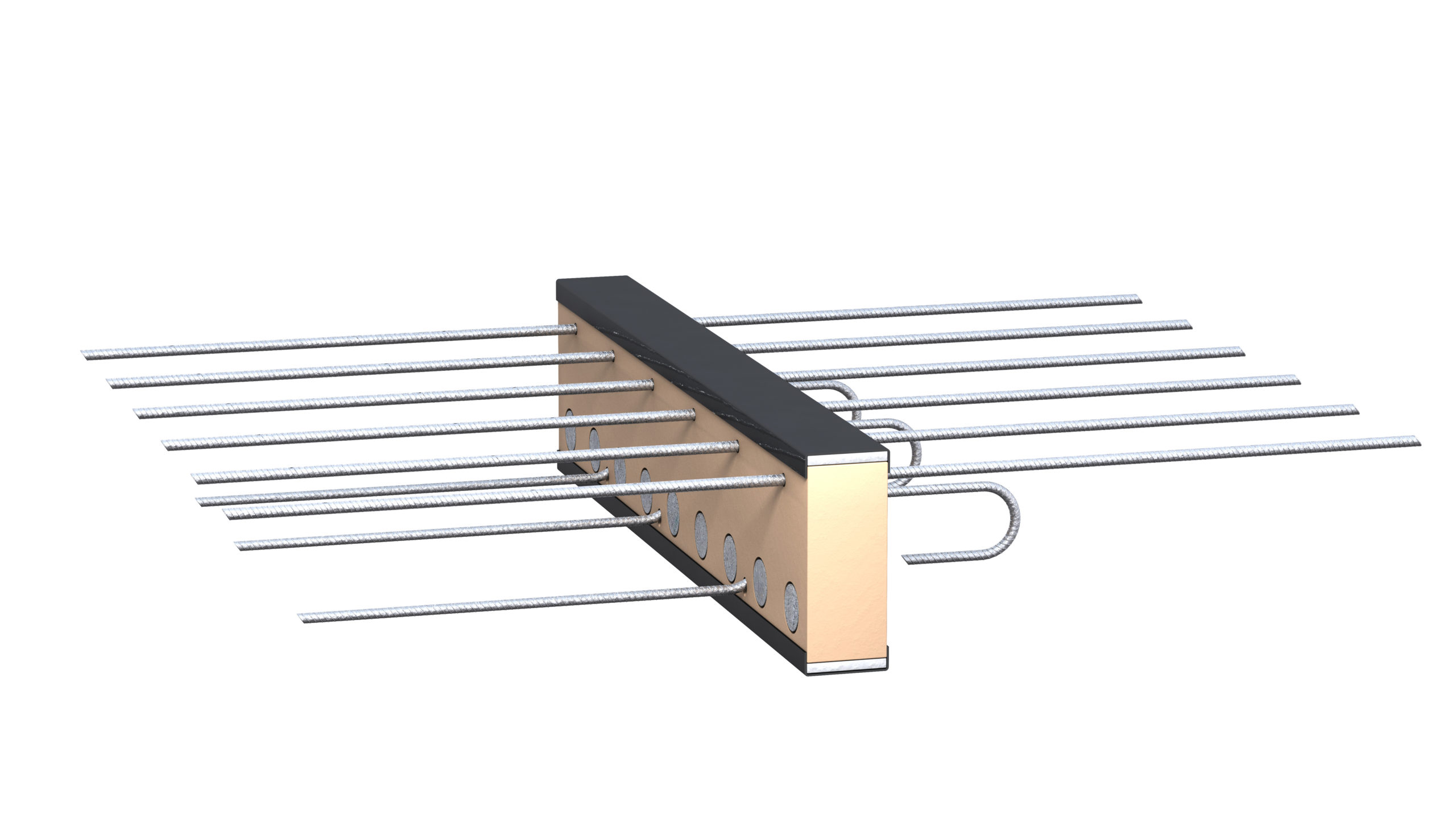

As the industry strives for net-zero carbon emissions, there’s a lot of discussion in the design community surrounding structural connections with thermal breaks. Many connections at balconies, parapets, canopies, column bases and other connections that pierce the building envelope create significant energy loss if they don’t incorporate thermal breaks.

Armatherm’s Range of Thermal Break Solutions

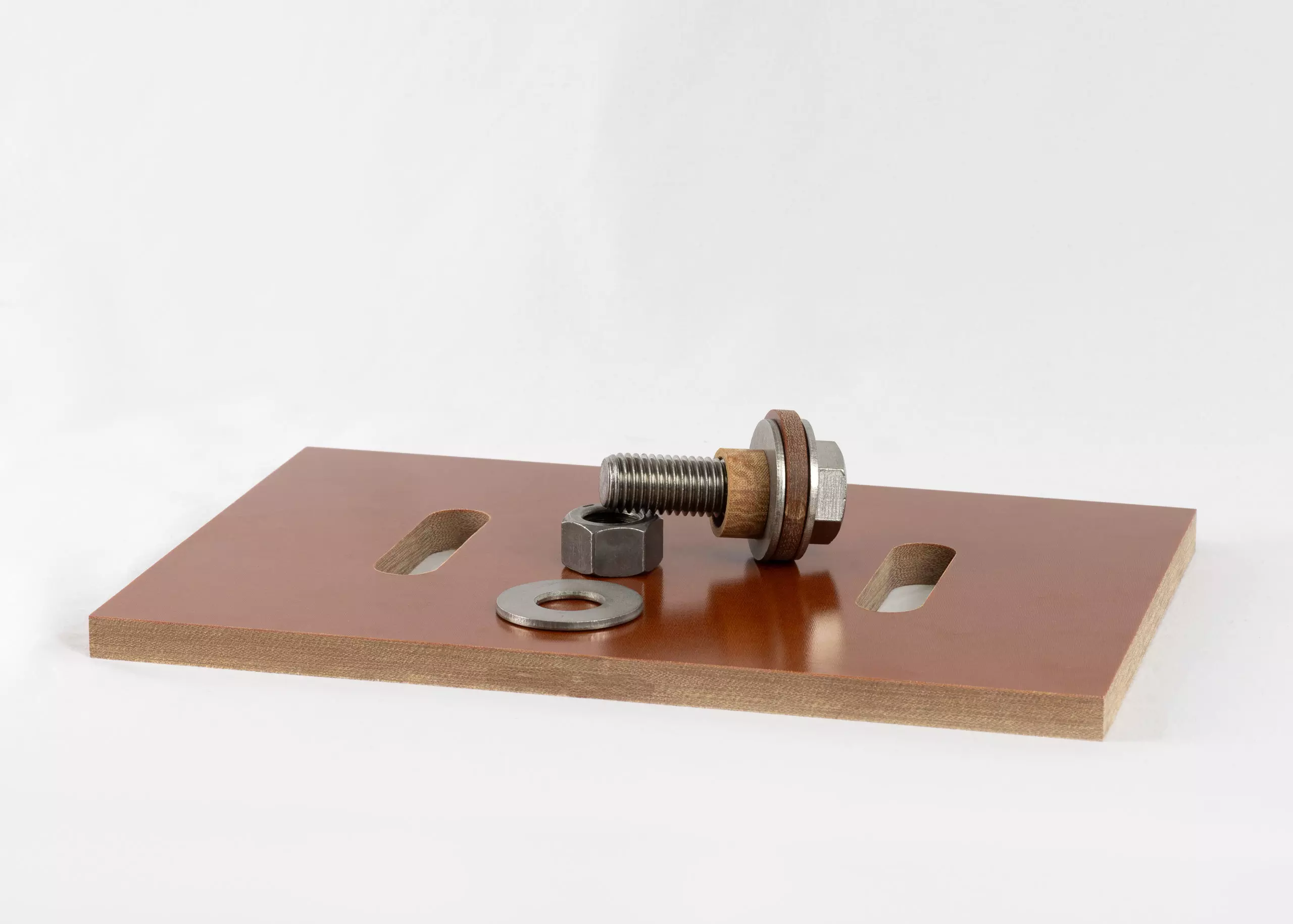

In response to the various stresses and conditions to account for, Armatherm set out to produce several structural, insulating products that can be cut to size and shape, and drilled as needed to address the various thermal bridging situations, including thermal break products that can hold up to tens of thousands of pounds of pressure per square inch. Additionally, we also produce lighter, higher-R value products that can withstand hundreds of psi and may be the better choice for thermal performance.

Armatherm has created a range of products that caters for the majority of requirements and applications. The solutions offer compressive strength at the higher and lower ends of the spectrum, meaning the right material can be specified for specific applications and meet the structural and insulating goals of the project.