Why choose

Armatherm™

Same day delivery option

Tested to ASTM standards

Stock always on hand

Code compliance

LEED benefits

Manufactured in the US

Our

Accreditations

Thermal

Break resources

Use the helpful resources on our website to better understand the significance of thermal break products, the salient characteristics of our products, and the applications to which they can be put to use. These resources include test reports, extensive literature libraries, design assistance, and product profile videos. If you need CAD drawings for your project, you can download them from the ArmathermTM website and quickly incorporate them into your designs.

The course provides an overview and introduction to thermal bridging, addressing how and why it occurs as well as how it may be prevented. Our user-friendly online thermal breaks webinar is also available online. It showcases and contrasts the difference between building details with and without thermal break solutions to demonstrate the necessity of determining accurate values of thermal transmittance.

Armatherm resources

Downloads

Request a quote

If you require a quotation and know the following product information, complete through form below.

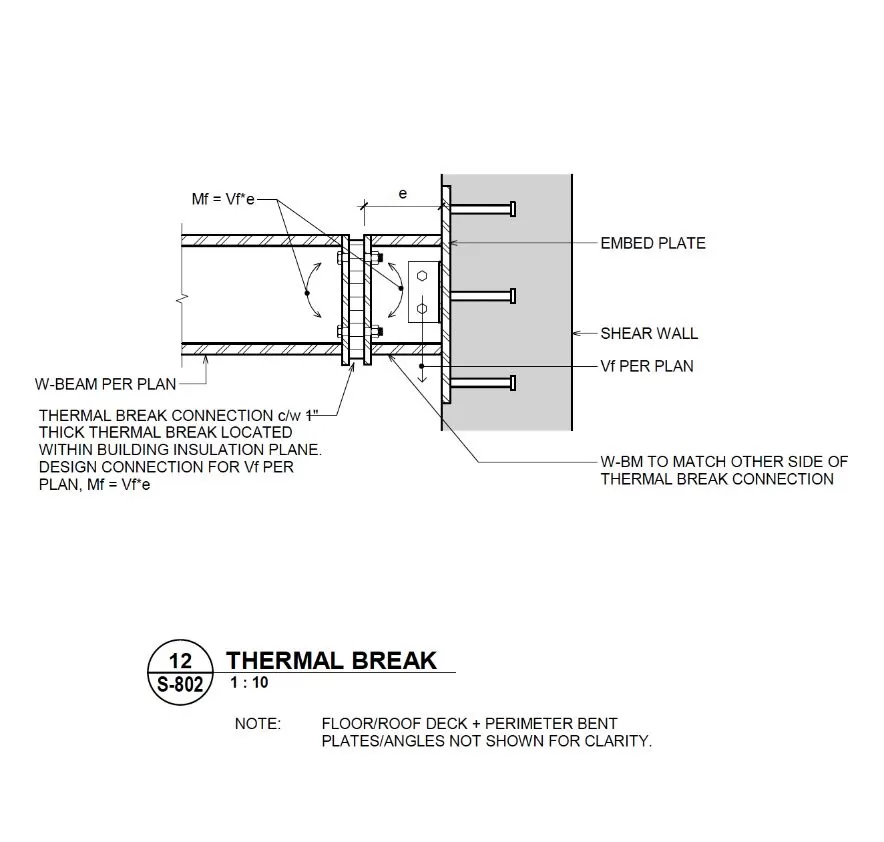

The strong thermal break solution material of Armatherm FRR is composed from thermoset resin. It provides low thermal conductivity and high compressive power. Due to the components that make up thermoset resin, it has various advantages, including low combustibility and less creep under load. As a result, it enhances energy efficiency and is especially useful in structural thermal break connections. Damaged condensation that results in mould growth and moisture buildup can be extremely dangerous. The most likely source of this condensation is a decreased heat flow within a building’s thermal envelope, which significantly lowers the energy consumption of the structure. Building energy performance statistics will be severely impacted by cold bridging, such as through concrete or steel framing. The FRR material from ArmathermTM has a flexible range of possible applications. It comes in a variety of forms to fit your project, including sheets, washers, and bushings, all of which have outstanding thermal isolation requirements. While they can be bonded together if your project calls for it, ArmathermTM FRR sheets satisfy the U value and thickness standard criteria. In addition to the standard thickness options of 12mm, 20mm, 25mm, and 50mm, this material is also available in 3mm, 6mm, 10mm, and 15mm, so whatever your need, the perfect material may be developed especially for you and your project. It is obvious that incorporating thermal break sheets into steel and concrete frame is crucial. In addition, the front side of the bol head, between the steel washer and the face of the outside steel, shall also have a thermal break specified. Thermal bridges across the bolt are preserved when thermal breaks are added at these spots. This would otherwise provide a path for heat to flow through the thermal break assembly and result in a loss of energy from inside the building. For reducing potential condensation as a result of these thermal bridges in the building envelopes, Armatherm™ washers and bushings are vital.

One of our high strength thermal fractures is ArmathermTM 500. It is made of a cutting-edge polyurethane material that has been produced in a variety of densities specifically to support a broad range of loading situations inside a building’s structure. Its enclosed cell construction does not absorb water and only very little creep occurs when under load. As a result, there is significantly less energy lost due to thermal bridging. There is a significant reduction in heat movement, energy usage, and potential condensation problems. Also available in sheet form is ArmathermTM500. It may be simply layered together to meet the required U value and thickness requirements. Because of its adaptability, it can be employed whenever there is a penetration or a thermal bridge where a transition exits through the building exterior. Parapets, slab/floor margins, roof penetrations, custom window sills, concrete balconies, among many more locations, are typical examples of these locations. The material is also dynamic and user-friendly; if necessary, it can be quickly cut and drilled on location. This might be crucial in cold storage facilities to keep the subgrade from freezing, in addition to being utilised to avoid cold bridges and maintain warm temperatures inside a building. Moreover, it might be positioned right beneath the base of the column to stop any temperature transfer into the earth.

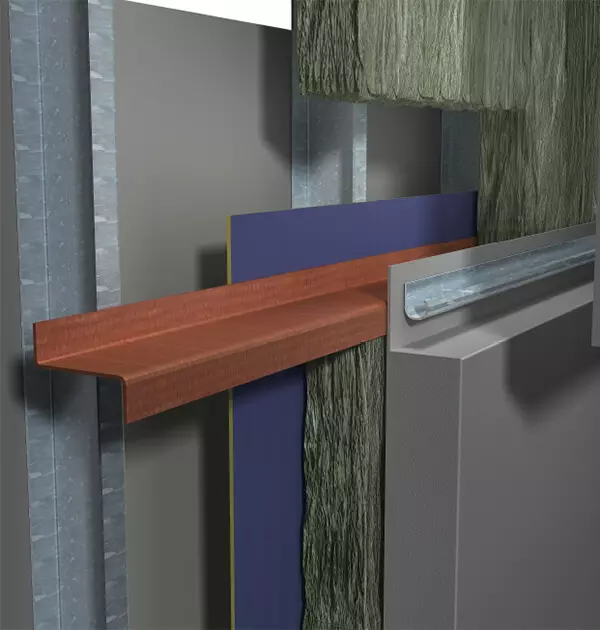

The ArmathermTMZ girt, a non-metallic thermal break, is the ideal choice for masonry or steel stud backings that are new or already present, as well as for external wall constructions. Z-girts boost the overall wall assembly’s effective R-value. They were created to stop heat from escaping through the building envelope. Tests show that using Z-girts, which are composed of fiber-reinforced plastic, can improve the thermal efficiency of the wall design in a number of ways. Reduced heat flow and energy transfers are part of this. The structural material has a classic Z-girt shape and is significantly more effective than its steel counterparts. It is used to support insulation and mount cladding. In fact, it provides an improvement of up to 75% over conventional steel Z-girts. For professionals looking for energy-efficient solutions, this non-conductive option is important. Wall assemblies that use ArmathermTM thermal break products can achieve efficiencies of up to 98%. Also, they are less likely to experience condensation and damp problems, which can seriously harm a property and the wellbeing of persons inside. Cladding attachments are greatly enhanced when a combination of thermal break items is specified. To maximise effectiveness everywhere, Z-girt, clips, and shims are all utilised.