Structural Thermal Breaks Supporting Sustainable Building Design

In modern day construction, energy efficiency and structural stability are a key concern, the construction industry is continually seeking intelligent solutions to enhance building envelope performance. One of the leading technologies being specified more and more to help in these areas is structural thermal breaks.

These innovative solutions play a significant role in minimizing heat transfer and thermal bridging within a building envelope, leading to improvements in energy efficiency, reduced impact on the environment and enhanced occupant and visitor comfort. There’s different types of thermal breaks, each one with the ability to minimize energy flow in connections throughout a construction project.

Material-based breaks

High-density polyurethane foam thermal breaks harbor superior thermal performance alongside high compressive strength. They’re suitable for use in slabs, roofs and other load bearing applications, providing both structural support and insulation. Armatherm 500 structural thermal break is a thermoset polyurethane manufactured in several densities with high strength properties. Armatherm 500 has a selection of four grades of material with different compressive strengths and R-values.

Reinforced fiberglass thermal breaks are lightweight, non-corrosive, east to install whilst offering effective insulation properties. This makes them a popular choice for façade and balcony connections. The ArmaGirt™ Z Girt is a great example of a fiberglass thermal break, it’s an ideal choice for furring exterior walls on a new or existing masonry, or steel stud backing. They were developed to reduce heat lost in a building envelope while increasing the overall R-value of the wall assembly.

Phenolic foam thermal breaks possess exceptional low smoke emission and fire-resistant properties. They’re most used in locations where fire safety is a primary concern, such as fire-rated partitions and walls. An example of a thermal break product which falls into this category is the Armatherm FRR material which can not only support high loads but has great mechanical properties as well as being fire resistant – making it ideal for use within structural steel and façade connections.

Isolated connections

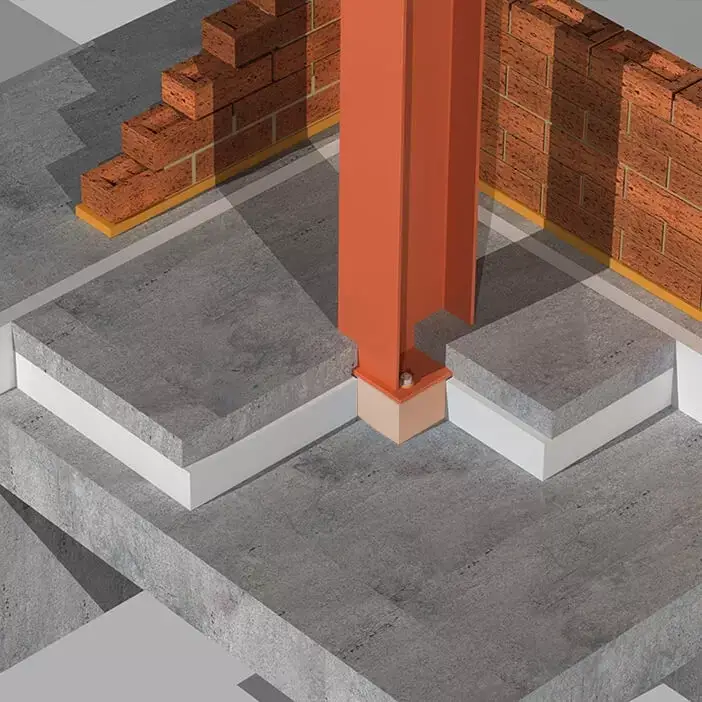

Steel-to-steel isolation is required anywhere that isolated materials are inserted into steel members, such as beams and columns. This method is prevalent in both commercial and industrial buildings which often will feature steel framework.

Concrete-to-concrete isolators and disconnectors can be used within reinforced concrete structures to separate concrete elements like slab and walls. With the weight properties of concrete, this is where a high load baring thermal break would be the ideal solution.

Hybrid thermal breaks

Hybrid thermal breaks are advanced building components that combine the principles of material-based and isolated connection thermal breaks to provide enhanced thermal performance alongside structural support. These intelligent materials have been designed and manufactured to address thermal bridging more effectively and optimize the thermal efficiency of buildings. They’re rapidly gaining popularity within the construction industry due to their versatility and ability to cater to specific requirements of a building. An example of a hybrid thermal break is a combination of an insulating material and isolators to minimize the heat transfer effectively. The previously mentioned ArmaGirt™ Z Girt is a prime example. Its primary objective is to reduce heat loss within a building envelope, but it also increases the effective R-value of the total wall assembly.

One of the most significant advantages of incorporating a structural thermal break solution throughout a project is enhanced energy efficiency within the building. By reducing heat transfer and the occurrence of thermal bridges, these components can work towards maintaining a more stable indoor temperature which reduces the need for costly heating or cooling methods. As a result, buildings with thermal breaks require much less energy to maintain comfortable indoor conditions, leading to decreased utility costs and lower energy consumption. If the inside temperatures are more agreeable and can stay at a preferred temperature for longer, there’s less need for any expensive heating and air condition solutions to be used as frequently.

Reduced energy consumption translates to lower cooling expenses for the building owner, and occupants too. With less heat loss being experienced during colder months, and a reduction in heat gain in the hotter months, buildings that contain effective thermal break solutions throughout can reap the benefits of improved thermal performance all year round.

Condensation is a key issue to address within a building. Thermal breaks work towards maintaining a higher surface temperature on the interior side of building components, reducing the risk of any condensation forming. If a thermal bridge is present, they can easily lead to cold spots on interior walls which is where condensation will appear when met with the warm and moist interior air temperatures. By reducing the chances of condensation forming on interior walls, the potential for mold growth, material degradation and any other moisture related issues is significantly reduced too, contributing to a healthier indoor environment.

By eliminating thermal bridging and cold spots near connections and building elements, structural thermal breaks create a more consistent and enjoyable, comfortable living space or indoor environment. Occupants experience fewer temperature fluctuations, leading to increased overall satisfaction with the building.

Thermal bridging can lead to localized stress and temperature-related wear and tear on building components, associated with condensation, potentially causing detrimental effects to their structural integrity over time. With the use of a structural thermal break, the stress on a building’s structure is reduced, extending the lifespan of critical building elements and minimizing any expensive repair and maintenance costs.

The addition of thermal breaks aligns with sustainable building practices and green design initiatives. Buildings featuring these energy-saving materials are more likely to achieve green building certifications and meet ever advancing energy codes. The USGBC’s LEED program and Passive House both recognize thermal bridging mitigation as a major milestone in building efficiency. They also work towards eradicating the need for any costly renovation projects to improve efficiency over time or in the future.

Structural thermal breaks come in a variety of forms, offering architects and designers flexibility in their application. They can be customized to suit various t building types, different connections, architectural styles, structural configurations and more to allow for seamless integration into a diverse range of construction projects.

Many building codes and energy efficiency regulations now emphasize the importance of addressing thermal bridging. By incorporating structural thermal breaks, builders and developers can comply with these requirements and ensure that projects they’re working on will meet all the necessary standards.

By embracing the most innovative energy solutions on the market, the construction industry fosters a culture of sustainability and responsible building practices. This cultural shift ultimately leads to a more sustainable and environmentally conscious future for the building industry.

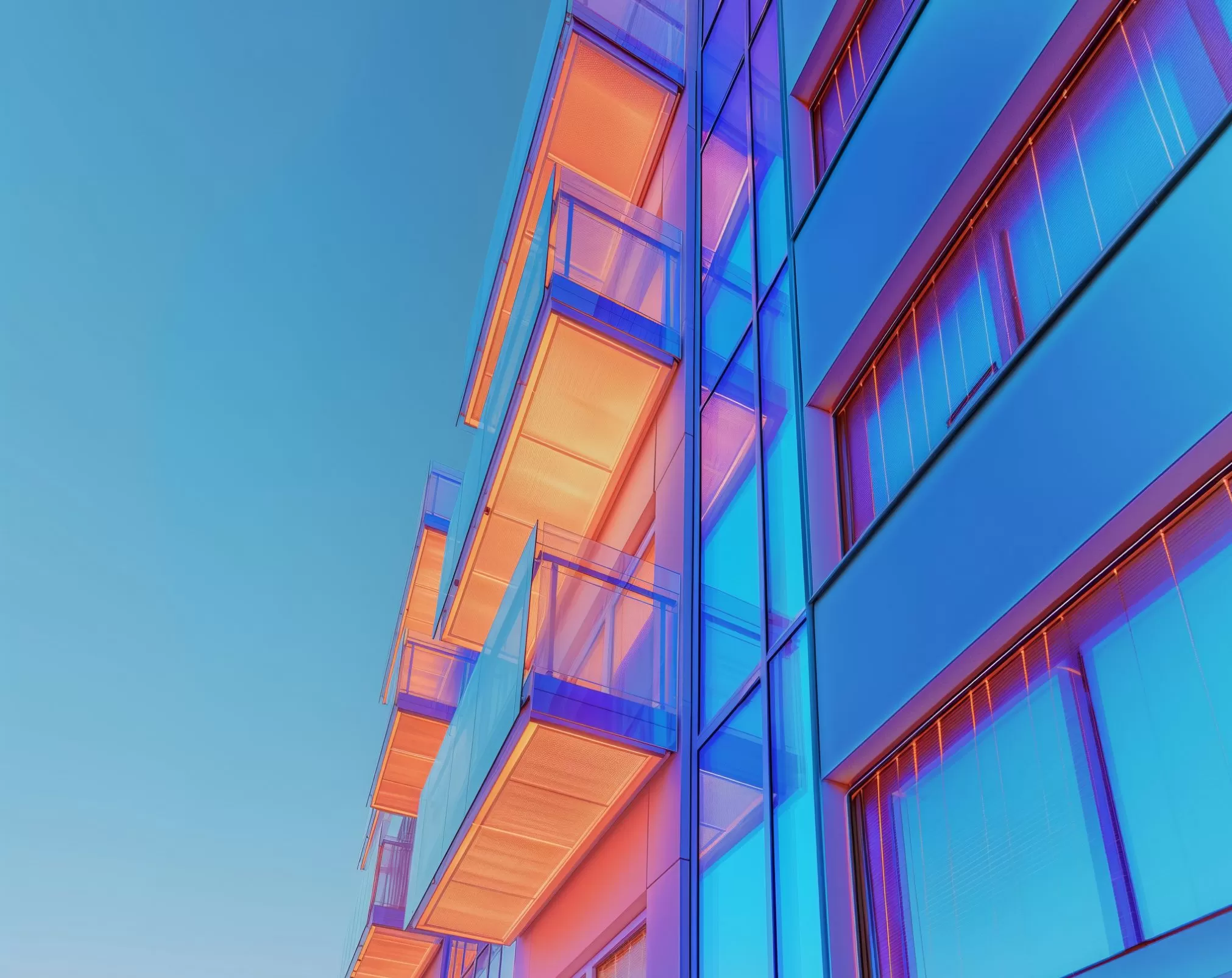

Structural thermal breaks can be used at connections between the building façade and the main structure of the building. By interrupting thermal bridges at these points, they crucially help maintain consistent indoor temperatures, reducing energy consumption and preventing condensation issues.

Roof to wall connections are common areas for thermal bridges to occur. Structural thermal breaks in these areas ensure that heat loss or gain is minimized, contributing to improved thermal performance and overall efficiency.

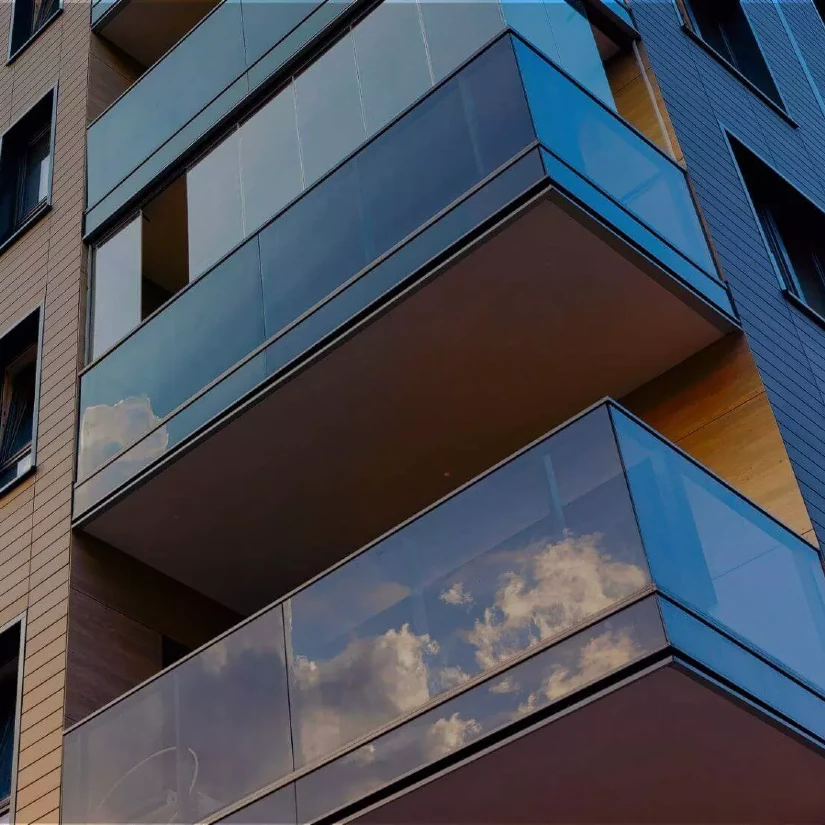

Balcony connections are notoriously known for creating thermal bridges between the interior and exterior of a building. Thermal breaks in balcony connections help reduce any heat transfer from occurring, preventing discomfort for occupants or visitors and enhancing the overall energy efficiency.

Integrating structural thermal breaks at slab edges and penetration, such as around windows and doors f, help maintain a continuous thermal barrier. This prevents localized heat loss or gain, creating a more comfortable indoor living environment and reducing heat and cooling costs.

Both these connections can act as thermal bridges if not adequately addressed. Structural thermal breaks in these areas minimize heat transfer and maintain the thermal integrity of the building envelope.

Innovations in science have led to the development and manufacturing of new and improved materials for structural thermal breaks.

Prefabrication techniques have made significant developments in the industry, and the same applies to structural thermal breaks. Armatherm offers prefabricated thermal break products, cut to size, and accurately drilled, and are ready to be installed. This saves time and money! Thermal break material can be provided in sheet stock and cut on site as well.

In addition, many manufacturers offer customizable thermal breaks tailored to specific project requirements, so a custom size and thickness can be specified. Engineers can collaborate with manufacturers to create thermal breaks that match any of a building’s unique structural details, ensuring an ideal fit for maximum performance. This flexibility allows for seamless integration within building elements like façades, and roofing systems.

Another significant development in structural thermal breaks is the integration of load transfer capabilities within the break systems system.

Engineers can now design thermal breaks that will provide thermal separation, alongside the ability to transfer loads between building components. This integration is key for structural stability, but also effectively minimizes thermal bridging.

This is particularly beneficial for building connections like façades and balconies, where both thermal performance and structural support are crucial. This approach optimizes the use of materials and streamlines the design process.

Continuous insulation systems have surfaced as a real game-changer in the fight against thermal bridging. They provide uninterrupted thermal insulation across the entirety of a building envelope, ensuring a consistent thermal barrier. Whether in masonry construction, curtain walls, or other façade systems, continuous insulation effectively reduces any potential heat loss or gain, resulting in remarkable efficiency improvement levels.

Continuous insulation solutions, when combined with other innovations like customisable thermal break pads and advanced insulating materials, create a highly efficient thermal envelope that complies with even the most stringent energy codes, regulations and certifications.

What part do structural thermal breaks play in creating a sustainable future for construction?

The importance of structural thermal breaks in creating a more sustainable future in the construction industry cannot be ignored. As we continue to combat climate change and reduce our ecological footprint, these intelligent components play a pivotal role in advancing energy-efficient and environmentally responsible construction methods. By mitigating thermal bridging, enhancing energy efficiency, and promoting green regulations, structural thermal breaks contribute to a more sustainable built environment. Their impact extends beyond energy savings, creating healthier indoor spaces and reducing environmental impact, these benefits should not be overlooked.

As construction and design professionals take the time to understand and learn about these innovations like thermal breaks, they take crucial steps towards building a sustainable future for generations to come. The adoption of structural thermal breaks marks a transformative shift in the construction industry – one that prioritizes both environmental preservation and economic prosperity. As the industry continues to embrace these sustainable solutions and work towards a more secure future, structural thermal breaks are poised to become an indispensable feature in building design, promoting a greener, more energy-efficient and overall brighter future.

To find out more about enhancing building efficiency and Armatherm’s thermal break materials, please contact Armatherm’s dedicated team using the details on our contact us page.